What is NanoFiber?

NanoFiber Is A Relatively New And Exciting Technology That Is Upturning Industries Around The World!

These tiny strips of material are created using a variety of techniques and methods that have been developed over hundreds of years. Around the year 1600, a man named William Gilbert observed how liquid behaved when affected by an electric field produced by rubbing against a piece of amber. When the amber was brought close to the liquid, it formed a shape now known as a Taylor cone (see Figure 1). After this initial discovery, there were many scientists and academics who saw the potential for future applications. In 1887, British physicist Charles Vernon Boys published a manuscript on the development of nanofibers and how it could be produced in the future. Boys' findings, along with many others, probably helped American inventor John Francis Cooley apply for the first modern electrospinning patent in 1900.

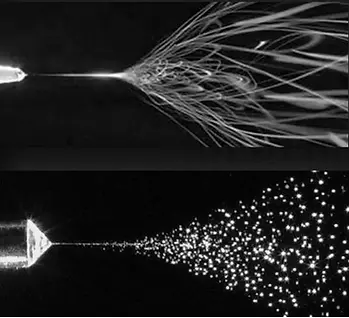

Figure 1: Taylor cone, transition zone and resulting liquid jet.

The first attempt to spin nanofibers was attempted by Anton Formhals until 1934. He later issued the first patent providing a detailed description of the experimental procedure for nanofiber production. This led to the first patent granted by Harold Simons in 1966 for a real machine capable of producing light and thin nanofiber fabrics on a larger scale. Since then, nanofiber has become well known in the scientific community and is constantly being developed. For more information on the history of nanofiber please click here.

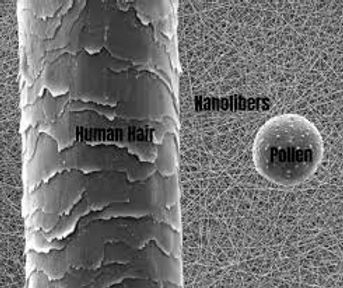

The nanofibers are usually about 50 to 500 nanometers in diameter, depending on the type of polymer used and the characteristics of the design. See Figure 2 on the right for some perspective. The small speck is a piece of pollen. The large strand on the left is not a nanofiber strand, but a piece of human hair with a diameter of about 75,000 nm. If you look closely, you can see a web of nanofibers in the background.

There is a wide variety of polymers and compounds used to create nanofibers such as polyurethane and lactic acid, as well as naturally occurring polymers such as collagen, cellulose, and gelatin. These polymers and others are used to develop and create a wide variety of technologies, including batteries, fuel cells, regenerative biotissue, and advanced liquid and air filtration. While these fibers are nearly impossible to detect with the naked eye, they can take up an enormous amount of surface area relative to the overall volume of the material. Nanofiber filters thus gain light and breathable properties, making them perfect for filtering out unwanted particles that can slip through traditional filter fabric.

Figure 2: Size comparison of a pollen particle with a strand of human hair. Nanofiber mesh in the background.

To a thin fiber filtration layerHaving has superior features. First, nanofiber filters have higher initial and sustained efficiency compared to conventional filters. They offer low pressure losses. They can be washed, their washing does not cause any wear and deformation. A nanofiber mesh can capture dust and other harmful particles much better than traditional fiber filters. They can achieve these high levels of filtration by using filtering methods such as stopping, diffusion, and multiplication. To learn more about filtering mechanisms please click here.

Another reason why nanofiber is superior is that filters using nanofiber layers have a longer life than other filters. Conventional filters reach the end of their life when the entire depth of the material is filled with debris. The nanofiber traps these particles at the surface and helps prevent them from clogging up other layers of material in the filter.

We also;

We produce the nanofiber mesh with a filter media consisting of a total 3-layer structure, protecting it between the breathable upper and lower mesh layer. Thus, the life of the filters is much longer.

Longer filter life means the user won't have to buy filters as often as before. Your energy consumption goes down. It extends the life of your systems and devices. So while many fine fiber filters have higher upfront costs, they can help save a significant amount of money in the long run.

What is NanoFiber?

Many different methods are used to form nanofibers, such as stencil synthesis, meltblowing, freeze-drying, and phase separation. The most commonly used technique is called electrospinning. Here, we spin our nanofiber from a base polymer. The process requires a high-voltage electric field whose ends are positively and negatively charged, similar to a magnet. The polymer is loaded into an extruder at one end of the field and quickly pulled out and stretched towards the oppositely charged end, forming a long, thin strand. This results in an ultra-fine nanofiber web that is spun directly onto a base layer for support and support.

Figure 3: Electrospinning (top) and electrospray (bottom)

(source:https://www.frontiersin.org)

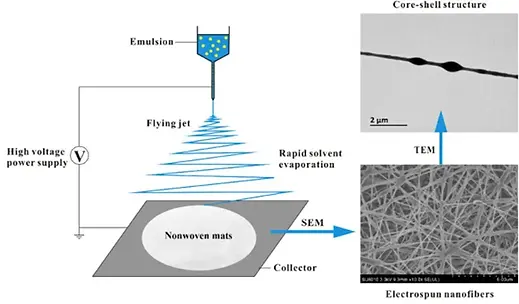

Figure 4: Electrospinning (top) and electrospray (bottom)

(source:https://www.frontiersin.org)

Figure 4 above shows how the electrospinning process is carried out. Emulsion, loaded. As soon as it leaves the applicator, it immediately forms a Taylor cone as a result of the high voltage power supply creating an electric field between the applicator and the collector. As the fluid moves into the field, it becomes more unstable and turns into a spiraling, flying jet. The fluid jet then descends on a mat of nonwoven material in this case. The nanofiber mesh will then be used in conjunction with other layers of material or on its own, whatever the design specifications require.

How Does Nanofiber Work?

When harmful particles such as dust, smoke, viruses and bacteria encounter the nanofiber layer, it is as if they have entered a cursed forest from which almost no one can escape. While these particles try to make their way through the dense matrix, the seemingly endless array of fibers can easily prevent them from passing through by mechanical filtration, unlike filters using electrostatic filtration methods.

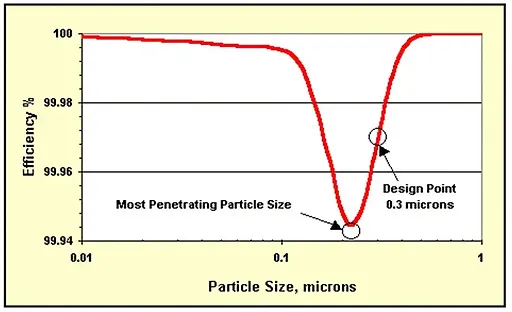

You will often hear mask manufacturers describe their products using efficacy and particle size. For example, N95 masks must meet a 95% filtration efficiency down to 0.3 microns to pass certification. But why 0.3 micron? Anything larger than 0.3 microns is pretty easy for filters to capture. For smaller particles, the threshold between 0.1 and 0.3 microns is the most challenging particle range for filters to capture (see Figure 5). When particles become smaller than 0.1 micron, they experience Brownian motion.

This phenomenon occurs when particles are so small that they change direction when they hit gas molecules. Brownian motion bounces particles so fast over such a short distance that they are almost guaranteed to enter the filter fibers.

Another way to think of it is that it acts as a fishing net. The web of continuous, overlapping fibers traps larger particles and prevents them from escaping on the other side. As more particles are trapped in the mesh, a kind of filter cake forms throughout the material. This helps improve the overall filtering efficiency of the media over time.

Figure 5: Typical performance of the HEPA 99.97% filter.

Mechanical and Electrostatic Filtration

There are many intrinsic properties that distinguish nanofiber from conventional filters. Besides being cost-effective and easy to manufacture, nanofiber meshes have high porosity and a large surface area to volume ratio. These properties make them extremely useful in applications such as protective clothing, energy storage, fiber optics and organic tissue engineering. The main difference of nanofiber filters from other filters is the type of filtering method used.

Many filters on the market today are designed to attract and capture particles uses electrostatic forces. This may sound great at first, but they are often not as effective as other filtration media as they are less effective at trapping larger particles such as dust and mold. As they catch more dust and debris, they begin to lose their static charge over time. As mentioned earlier, mechanical filters such as our nanofiber material tend to have higher initial efficiency that does not decrease rapidly over time. This provides longer filter life and cleaner air output.

A Perfect Union

All of our products are produced using our nanofiber technology, they are unique.

Our Air Conditioning systems and Ventilation (HVAC) Air Filters, made with thicker nanofiber strips for better durability and tensile strength.

Regardless of the design features, these nanofiber layers are the key to our high quality, mechanically efficient filter media and HVAC filters. All of our nanofiber filters are washable filters. Our HVAC filters target 85% efficiency for particles as small as 1.0 micron. This is the MERV rating of 13. How filters are classifiedTo learn more about click here.

We use aluminum in the frames of our nanofiber filters. We produce frames in standard sizes and special sizes for use in all HVAC devices.

We produce nanofiber filters for air handling units, Fancoil units, Rooftop Air Conditioners, Heat Pumps, Heat Recovery Devices, Precision Air Conditioners and all other HVAC Air Conditioning and Ventilation devices.

With the birth of this new nanofiber technology, many people ask, "Is nanofiber safe?" she wonders. Especially when it comes to breathing through. The main concern is that pieces of the nanofiber mesh break off and enter the user's lungs. It is a common misconception that the material consists of many small, individual fibers, whereas in reality, as discussed earlier, it is really a single continuous piece of polymer overlapped over and over like a long strip of spaghetti. If the material is cut this can create more individual fibers, but these will still adhere to the backing layer they were originally spun onto, so you don't have to worry about them falling out. We also put filters to the test before the final stages of production. Conventional filters, fibers and polyurethane etc. respiration is done by easily breaking down into small particles. For this reason, nanofiber filters are very safe and healthy compared to traditional filters.

Thanks for reading!

We are passionate about helping people stay healthy and improving the quality of the air they breathe. Our filter products are designed to help keep you and your family safe by filtering out bad particles from the air. It also extends the life of your system and devices considerably. Our mission is to provide quality air filtration products to all consumers. For more information about our products and mission, visit our website at icsmuhendislik.net or send us an e-mail at info@icsistem.com. We look forward to hearing from you!

Our NanoFiber Filters

The usage area of our nanofiber filters is very wide. Hospitals, Hotels, Factories, Pharmaceutical Factories and Warehouses, Health Institutions, Government Institutions, Plazas, Workplaces and even houses..

You can find sample filter pictures and videos from our customers below. For more pictures and videos about our nanofiber filters, you can send an e-mail to info@icsistem.com.

.png)